Plant

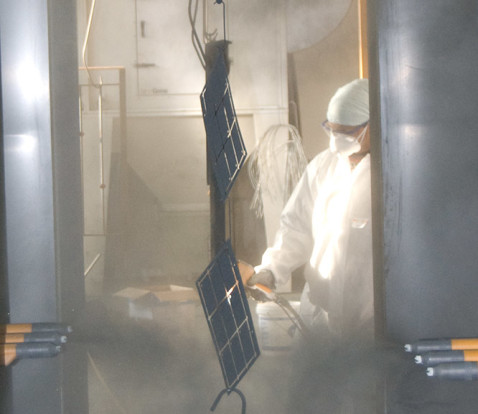

Since 2003, New Color has had a truly advanced powder painting plant (built by Officine Munari of Vicenza) and this plant was further upgraded in 2006. In terms of technology and production capacity, this plant is currently considered the most innovative in the field. It is an exclusive product which, in the Tre Venezie zone, is unequalled for subcontracting works.

With a 22 meter long feed track and an imposing front-feed tunnel, the plant can paint pieces up to 12 meters in length, 2.60 meters in height and weighing a maximum of 1500 kg. Thus it can treat a wide variety of materials, using modern, computerized technologies.

The new plant is composed of:

- a thermostatic curing oven of the following dimensions: 29,300x10,500x45,400

- a washing section with tank for acid cleaning of galvanized materials

- degreasing section that uses a phosphorous-based cleaning agent

- rinsing, and DEMI rinse section

- passivation section

- painting cabin with 12 industrial robots and manual touch-up spray guns

- computerized control of all phases of the process, even able to print out documents regarding each individual piece produced

In order to guarantee resistance in time and uniform results, New Color uses high quality powder paints, all strictly non-toxic and compliant with European standards; for products that are exposed to the elements and the weather, it uses Pulverlac polyester powders.

The powders used are all produced by certified companies.